In this article, we will delve into the basics of CIJ technology, how it works, and its applications across different industries.

Continuous Inkjet Printing (CIJ) is a versatile and widely used printing technology that operates on the principle of emitting continuous droplets of ink through a small nozzle onto a substrate. The process involves the following key steps:

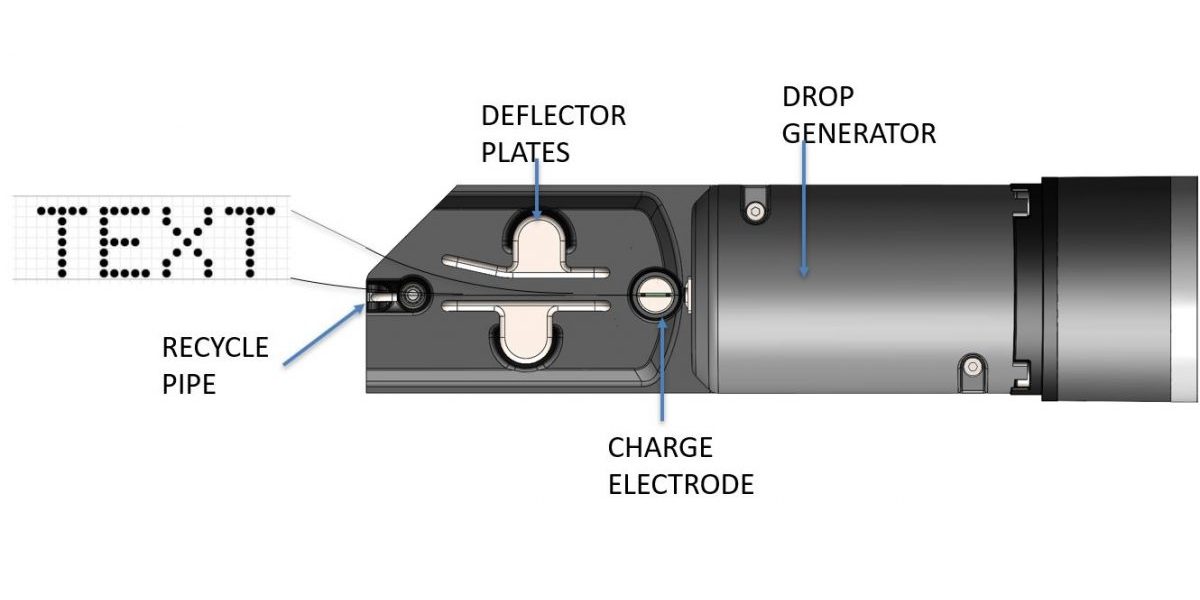

- Droplet Formation: A high-pressure pump forces ink from a reservoir through a tiny nozzle, creating a continuous stream of liquid ink about the size of a human hair. The ink stream is vibrated with ultrasound, which turns it into droplets. Around 80 000 droplets are produced every second.

- Droplet Charging: An electrode near the nozzle selectively charges the droplets as they are formed.

- Droplet Deflection The charged droplets are then subjected to an electrostatic field, which deflects them a distance based on their charge – the more charge the more deflection. Uncharged drops are collected and recycled back into the ink system.

- Printing on Substrate: The charged droplets leave the printhead and form the desired pattern or text when they reach the substrate.

CIJ is renowned for its large throw distances (the distance from printhead to substrate), enabling it to print on various substrates of any shapes without the need for complicated handling systems to keep the substrate flat. Substrates include paper, plastics, glass, metal, and more. It offers high-speed printing capabilities, making it suitable for applications requiring rapid output such as automated production lines.

In terms of applications, CIJ finds widespread use across diverse industries. In packaging, it is employed for product labelling, barcoding, and expiration date printing. In the food and beverage industry, CIJ ensures compliance with regulations and enhances product traceability. In the pharmaceutical sector, it is used for printing batch numbers and serial codes on medicines and packaging. Additionally, CIJ is instrumental in industrial manufacturing, where it marks products with serial numbers, manufacturing dates, and brand logos.

Moreover, CIJ is crucial in coding and marking applications for electronics, automotive, and aerospace industries, where durable and high-resolution printing is necessary for circuit boards, automotive parts, and aircraft components.

In summary, Continuous Inkjet Printing operates on the principle of jetting charged ink droplets onto a substrate, allowing for non-contact and high-speed printing. Its applications span various industries, including packaging, food and beverage, pharmaceuticals, electronics, automotive, and aerospace, making it an indispensable tool for marking and coding needs.